Processing services for ITO and FTO glass

Learn about our latest pieces

-

With CNC milling, we can precisely machine the surface of glass to a designated depth, enabling the production of high-precision packaging components for electronic applications.

-

We provide precision drilling for glass of different thicknesses, with hole diameters achievable below 0.5 mm.

-

Using advanced CNC technology, we are capable of machining glass into virtually any shape—such as circular or concave designs—while maintaining dimensional tolerances within 50 microns.

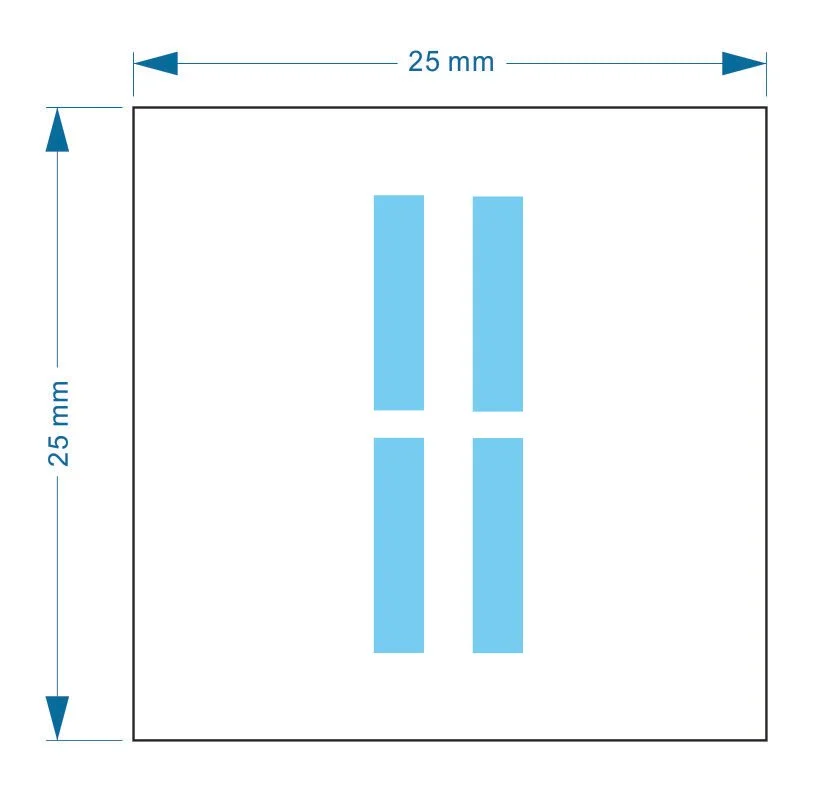

Patterning

Patterns on ITO coated substrates consist of coupons with ITO and ITO free areas. These components are used for test purposes in R&D projects and as devices in electronic equipment.

They are usually produced by the selective removal of ITO from continuously coated ITO sheet by photolithographic or laser ablation methods.

-

We can perform etching on a wide range of materials, including FTO glass, ITO glass, ITO PET film, and other transparent or opaque substrates with conductive layers.

-

Our laser etching process allows for pattern line widths and spacings below 50 microns, ensuring high-resolution precision.

-

Based on your design specifications and material requirements, we can usually complete and deliver the sample within one week.

Special Offers and Programs.

New Lab Start-Up Program

Get access special offers plus services to keep your new lab running smoothly- Check if you qualify.

10% Off for New Customers

Benefit from 10% discount on any online order for new customers - Contact us today.

Get a Special Offer When You Order in Bulk

Get special pricing when you order products from MSE Supplies in bulk. Contact us to claim it.

The above-mentioned promotional offers will significantly reduce your expenses.If you would like to purchase samples, you can place an order directly from our Amazon store. We have the industry’s best tech support to answer your questions. Contact us online or call (+81) 90-5217-0026,Same number for WhatsApp and LINE.

ITO (Indium Tin Oxide) glass Cutting process

After milling non-conductive glass.